Cleaning Machines Karcher

All models Advanced filters → |

You might be interested in

Cleaning Machines: specifications, types

Show all

Type

Classic cleaning machines (not robots) in our time can be of the following types: street sweepers, sweeper-suction machines, floor scrubbers, as well as window cleaning devices (“ window vacuum cleaners ”). In addition, special cleaning robots are produced - for windows, for cleaning the pool. Here's a more detailed description of each of these options:

– Sweeper. Machines that operate on the broom principle: moving brushes sweep away debris from the floor, sidewalk or other surface, collecting it in a special container. Such units are extremely simple, most of them generally have a mechanical drive (see below). And from the simplicity of the design comes such advantages as low weight, low cost, reliability and ease of maintenance/repair. On the other hand, in terms of cleaning efficiency, such equipment is inferior to the same sweeping and suction devices. We emphasize that most models in this category are designed for large open spaces, including outdoors; for small cleaning volumes and with an abundance of hard-to-reach places, it is better to use the household version of sweepers (see below)

— Sweeping and suction. Machines that combine sweeping and suction in operation, in other words, they work simultaneously as a broom and a vacuum cleaner: debr...is and dust are collected by brushes, then, due to the flow of air, the collected material is drawn into the garbage container. This increases the cleaning efficiency compared to “pure sweeping” units, but the machines themselves are heavier and more expensive, and a mechanical drive is not applicable to them - an engine is required to operate the suction system.

– Floor scrubber. Machines for wet cleaning of non-carpeted floors (linoleum, laminate, marble, etc.). A classic scrubber dryer works as follows: water with detergent is supplied to the floor through a sprayer at the front of the unit, the moistened surface is brushed, after which the dirty water is collected by a special device (suction beam) at the rear of the device and drawn into a separate tank. Thus, a clean, quickly drying floor is immediately left behind the machine. In addition, this category also includes so-called floor polishers - devices designed to treat the floor mainly using rotating brushes. Such units may provide the ability to supply water or detergent to the brush, but there is no suction system; So floor polishers were originally intended for relatively simple cleaning, as well as rubbing and polishing non-carpet surfaces. At the same time, it is worth noting that some of these devices are very versatile; they can be equipped with various additional attachments and accessories - including discs for cleaning carpets and even a vacuum cleaner module that turns the floor polisher into a sweeper-suction machine (see above).

– For windows. Devices for manual window cleaning, reminiscent of compact vacuum cleaners. This type of washing is carried out as follows: liquid detergent is applied to the glass from a spray bottle, then the liquid along with dirt is collected from the glass using this “window vacuum cleaner”. The sprayer is often built-in, but in some models it is a separate container with a sprayer supplied in the kit.

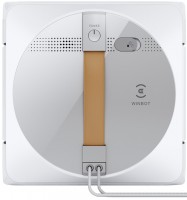

— Robot for windows. Automatic window cleaning devices: the robot attaches to the glass and moves along it, wiping the glass in the process. Such a device greatly simplifies the cleaning process, and for residents of high-rise buildings it can be a real salvation: with the help of a robot, you can easily wipe the windows from the outside on any floor, without the risk of falling out of the window and without calling industrial climbers. True, such devices can leave dirt around the edges and corners of the frame - however, eliminating these shortcomings is easier than washing the entire glass.

— Robot for swimming pools. Specialized units for automatic cleaning of swimming pools. As a rule, they are designed for use under water and do not require emptying the pool for cleaning; Often the design provides not only the ability to clean surfaces, but also water filtration. Robots, as a rule, have programs for self-cleaning - however, in addition to this, it is often possible to force the unit to be sent to one or another part of the pool, or even completely manual control. Many advanced devices in this category are capable of moving not only along the bottom, but also along the walls, rising to the very surface and thereby providing effective cleaning of the waterline.

We emphasize that although robots of this type are usually designed for maximum safety, you cannot use the pool while cleaning. It is also worth noting that such devices are usually powered from the mains - through a power supply and a special waterproof cable. Among other things, this design allows you to pull the unit out of the water directly by the wire in an emergency (although under normal conditions this should not be done).

– Sweeper. Machines that operate on the broom principle: moving brushes sweep away debris from the floor, sidewalk or other surface, collecting it in a special container. Such units are extremely simple, most of them generally have a mechanical drive (see below). And from the simplicity of the design comes such advantages as low weight, low cost, reliability and ease of maintenance/repair. On the other hand, in terms of cleaning efficiency, such equipment is inferior to the same sweeping and suction devices. We emphasize that most models in this category are designed for large open spaces, including outdoors; for small cleaning volumes and with an abundance of hard-to-reach places, it is better to use the household version of sweepers (see below)

— Sweeping and suction. Machines that combine sweeping and suction in operation, in other words, they work simultaneously as a broom and a vacuum cleaner: debr...is and dust are collected by brushes, then, due to the flow of air, the collected material is drawn into the garbage container. This increases the cleaning efficiency compared to “pure sweeping” units, but the machines themselves are heavier and more expensive, and a mechanical drive is not applicable to them - an engine is required to operate the suction system.

– Floor scrubber. Machines for wet cleaning of non-carpeted floors (linoleum, laminate, marble, etc.). A classic scrubber dryer works as follows: water with detergent is supplied to the floor through a sprayer at the front of the unit, the moistened surface is brushed, after which the dirty water is collected by a special device (suction beam) at the rear of the device and drawn into a separate tank. Thus, a clean, quickly drying floor is immediately left behind the machine. In addition, this category also includes so-called floor polishers - devices designed to treat the floor mainly using rotating brushes. Such units may provide the ability to supply water or detergent to the brush, but there is no suction system; So floor polishers were originally intended for relatively simple cleaning, as well as rubbing and polishing non-carpet surfaces. At the same time, it is worth noting that some of these devices are very versatile; they can be equipped with various additional attachments and accessories - including discs for cleaning carpets and even a vacuum cleaner module that turns the floor polisher into a sweeper-suction machine (see above).

– For windows. Devices for manual window cleaning, reminiscent of compact vacuum cleaners. This type of washing is carried out as follows: liquid detergent is applied to the glass from a spray bottle, then the liquid along with dirt is collected from the glass using this “window vacuum cleaner”. The sprayer is often built-in, but in some models it is a separate container with a sprayer supplied in the kit.

— Robot for windows. Automatic window cleaning devices: the robot attaches to the glass and moves along it, wiping the glass in the process. Such a device greatly simplifies the cleaning process, and for residents of high-rise buildings it can be a real salvation: with the help of a robot, you can easily wipe the windows from the outside on any floor, without the risk of falling out of the window and without calling industrial climbers. True, such devices can leave dirt around the edges and corners of the frame - however, eliminating these shortcomings is easier than washing the entire glass.

— Robot for swimming pools. Specialized units for automatic cleaning of swimming pools. As a rule, they are designed for use under water and do not require emptying the pool for cleaning; Often the design provides not only the ability to clean surfaces, but also water filtration. Robots, as a rule, have programs for self-cleaning - however, in addition to this, it is often possible to force the unit to be sent to one or another part of the pool, or even completely manual control. Many advanced devices in this category are capable of moving not only along the bottom, but also along the walls, rising to the very surface and thereby providing effective cleaning of the waterline.

We emphasize that although robots of this type are usually designed for maximum safety, you cannot use the pool while cleaning. It is also worth noting that such devices are usually powered from the mains - through a power supply and a special waterproof cable. Among other things, this design allows you to pull the unit out of the water directly by the wire in an emergency (although under normal conditions this should not be done).

Power supply

— Network. Connection to a regular household outlet. The advantage of this option is its almost unlimited operating time. On the other hand, the power cord limits mobility and does not allow you to move away from sockets, and in their absence the device becomes useless. In addition, in some cases, the power cord can interfere with operation - for example, it will be clearly unnecessary for a heavy machine with a steering wheel and an operator's seat.

— Battery. Battery-powered devices are extremely mobile: they do not depend on sockets and do not have a wire that limits movement. In addition, the absence of a wire has a positive effect on the overall convenience of work - it “doesn’t fit into your hand.” On the other hand, the continuous operation time of such a device is limited by the battery charge, and the machines themselves are heavier, bulkier and more expensive than similar mains-powered models. However, in some cases, the described advantages have a decisive advantage over the disadvantages: in particular, scrubber-drying robots (see “Type”), as well as heavy professional machines with steering control (see below), are powered by a battery.

— Network/battery. Devices that can operate both from the mains and from a built-in battery. The features of these types of nutrition are described in detail above; and their combination is used quite rarely. In particular, this method of power...supply is provided in some window robots: the device uses a battery as standard, but if it is possible to run a wire, you can connect it to the network, saving battery power.

— Battery. Battery-powered devices are extremely mobile: they do not depend on sockets and do not have a wire that limits movement. In addition, the absence of a wire has a positive effect on the overall convenience of work - it “doesn’t fit into your hand.” On the other hand, the continuous operation time of such a device is limited by the battery charge, and the machines themselves are heavier, bulkier and more expensive than similar mains-powered models. However, in some cases, the described advantages have a decisive advantage over the disadvantages: in particular, scrubber-drying robots (see “Type”), as well as heavy professional machines with steering control (see below), are powered by a battery.

— Network/battery. Devices that can operate both from the mains and from a built-in battery. The features of these types of nutrition are described in detail above; and their combination is used quite rarely. In particular, this method of power...supply is provided in some window robots: the device uses a battery as standard, but if it is possible to run a wire, you can connect it to the network, saving battery power.

Controls

The control method provided for in the design of the machine.

Note that for models with simple manual control (when the user holds the handle and thus directs the machine), as well as for robots controlled exclusively from their own built-in panel, this parameter is not indicated; it is given only for units with more advanced options. For traditional harvesting machines, this may be the steering ; in turn, robots (see “Type”) can be controlled from a remote control and/or smartphone. Here's a more detailed description of these options:

- Steering. Control using a steering wheel or steering wheel. Used in heavy productive self-propelled equipment (see below), which would be difficult to deploy manually. Many of these models even have an operator seat and are essentially mini harvesting tractors of sorts. However, there are also units for which the operator must walk while working - they are somewhat less convenient to use, but are more compact, lightweight and inexpensive.

- Remote control. Control using a separate remote control supplied in the kit. More often, communication is carried out via an infrared channel - similar to remote controls for televisions, air conditioners, etc.; however, other options are possible. In general, the functionality of such control is quite limited compared to another option used in robots - control from a smartpho...ne (see below): from the remote control, as a rule, only a selection of preset operating programs, simple settings, and in some models - also direct motion control. On the other hand, such control is relatively inexpensive, and for most cases it is more than enough.

- From a smartphone. Control the robot from a smartphone or other similar gadget (for example, a tablet) with a special application installed on it; Communication is usually carried out via Bluetooth. This method turns out to be much more convenient and visual than using a remote control: in particular, the application can implement many additional functions that are not available with a traditional remote control (cartography with manual routing on a map of the room, scheduled cleaning, etc.). On the other hand, supporting such control affects the overall cost of the unit; and in the absence of a suitable control gadget, the robot becomes completely useless. Therefore, this option is rarely found in its pure form - much more often the ability to work with a smartphone is provided simultaneously with the remote control (see below for more details).

— Remote control / from a smartphone. Devices that support both control methods described above. This option is as versatile as possible: when working with basic functions, you can get by with the remote control, and for advanced settings, use an external gadget. At the same time, the remote control is initially included in the delivery package, thanks to which the unit can be used without a smartphone - for example, if a suitable smartphone is not on the household, or if you do not want to bother with installing and configuring the application.

Note that for models with simple manual control (when the user holds the handle and thus directs the machine), as well as for robots controlled exclusively from their own built-in panel, this parameter is not indicated; it is given only for units with more advanced options. For traditional harvesting machines, this may be the steering ; in turn, robots (see “Type”) can be controlled from a remote control and/or smartphone. Here's a more detailed description of these options:

- Steering. Control using a steering wheel or steering wheel. Used in heavy productive self-propelled equipment (see below), which would be difficult to deploy manually. Many of these models even have an operator seat and are essentially mini harvesting tractors of sorts. However, there are also units for which the operator must walk while working - they are somewhat less convenient to use, but are more compact, lightweight and inexpensive.

- Remote control. Control using a separate remote control supplied in the kit. More often, communication is carried out via an infrared channel - similar to remote controls for televisions, air conditioners, etc.; however, other options are possible. In general, the functionality of such control is quite limited compared to another option used in robots - control from a smartpho...ne (see below): from the remote control, as a rule, only a selection of preset operating programs, simple settings, and in some models - also direct motion control. On the other hand, such control is relatively inexpensive, and for most cases it is more than enough.

- From a smartphone. Control the robot from a smartphone or other similar gadget (for example, a tablet) with a special application installed on it; Communication is usually carried out via Bluetooth. This method turns out to be much more convenient and visual than using a remote control: in particular, the application can implement many additional functions that are not available with a traditional remote control (cartography with manual routing on a map of the room, scheduled cleaning, etc.). On the other hand, supporting such control affects the overall cost of the unit; and in the absence of a suitable control gadget, the robot becomes completely useless. Therefore, this option is rarely found in its pure form - much more often the ability to work with a smartphone is provided simultaneously with the remote control (see below for more details).

— Remote control / from a smartphone. Devices that support both control methods described above. This option is as versatile as possible: when working with basic functions, you can get by with the remote control, and for advanced settings, use an external gadget. At the same time, the remote control is initially included in the delivery package, thanks to which the unit can be used without a smartphone - for example, if a suitable smartphone is not on the household, or if you do not want to bother with installing and configuring the application.

Mechanical drive

The presence of a mechanical drive in the machine.

This feature is found predominantly in sweepers (see "Type"). Mechanically driven models look like lawnmowers: they have a distinctive low body on wheels and a handle. During operation, the user pushes such a machine in front of him, and the rotation from the wheels is transmitted to the brushes. Devices with a similar design have low performance; on the other hand, they are extremely simple, inexpensive, and completely independent of power sources. Some of these models may also have a battery-powered electric motor but the device can still be used mechanically when needed (for example, if the battery is removed for charging).

This feature is found predominantly in sweepers (see "Type"). Mechanically driven models look like lawnmowers: they have a distinctive low body on wheels and a handle. During operation, the user pushes such a machine in front of him, and the rotation from the wheels is transmitted to the brushes. Devices with a similar design have low performance; on the other hand, they are extremely simple, inexpensive, and completely independent of power sources. Some of these models may also have a battery-powered electric motor but the device can still be used mechanically when needed (for example, if the battery is removed for charging).

Self-propelled

This category includes machines in which the motor not only ensures the operation of the main mechanisms but also rotates the wheels, moving the unit forward. The advantage of this design is obvious: the operator does not need to manually move the machine during operation, which provides additional convenience and reduces fatigue. It is important for heavy professional models, which would be problematic to move manually. And models with steering (see below) can only be self-propelled.

On the other hand, units of this type require more powerful and heavier motors than non-self-propelled ones (after all, the motor power should be enough for both the main task and movement), they are more complex in design and control and also more expensive. Therefore, this feature is common predominantly in professional models, where the ability of the machine to move independently is a critical necessity.

On the other hand, units of this type require more powerful and heavier motors than non-self-propelled ones (after all, the motor power should be enough for both the main task and movement), they are more complex in design and control and also more expensive. Therefore, this feature is common predominantly in professional models, where the ability of the machine to move independently is a critical necessity.

Max. speed

The highest speed developed when operating a harvesting machine that has a self-propelled design (see above).

On the one hand, moving quickly could have a positive effect on productivity by reducing cleaning time. On the other hand, thorough cleaning in itself is poorly compatible with high speed of movement: this would require extremely powerful, expensive and heavy equipment, which is irrational to use in cleaning machines. In addition, high speed can be inconvenient and even dangerous for the operator and surrounding people; This is especially true when steering, see above. Therefore, this indicator in modern cleaning machines, as a rule, does not exceed 7 km/h - this is the speed of fast walking.

On the one hand, moving quickly could have a positive effect on productivity by reducing cleaning time. On the other hand, thorough cleaning in itself is poorly compatible with high speed of movement: this would require extremely powerful, expensive and heavy equipment, which is irrational to use in cleaning machines. In addition, high speed can be inconvenient and even dangerous for the operator and surrounding people; This is especially true when steering, see above. Therefore, this indicator in modern cleaning machines, as a rule, does not exceed 7 km/h - this is the speed of fast walking.

Max. slope

The maximum steepness of the climb that a self-propelled harvesting machine (see above) can overcome “without outside help”, solely on its own power.

The rise in this case is indicated in the same way as in the traffic rules - as a percentage. Let's remember that this number indicates how much the height changes per 100 m of ascent: for example, a slope of 12% means that 100 m of the path gives an increase in height by 12 m.

Modern harvesters don't often have to work on steep inclines. Therefore, in most models this figure does not exceed the 12% mentioned above (although values up to 18% are found). It makes sense to pay attention to this indicator if you often have to work on steep climbs - for example, entrances to underground garages, warehouse ramps, etc.

The rise in this case is indicated in the same way as in the traffic rules - as a percentage. Let's remember that this number indicates how much the height changes per 100 m of ascent: for example, a slope of 12% means that 100 m of the path gives an increase in height by 12 m.

Modern harvesters don't often have to work on steep inclines. Therefore, in most models this figure does not exceed the 12% mentioned above (although values up to 18% are found). It makes sense to pay attention to this indicator if you often have to work on steep climbs - for example, entrances to underground garages, warehouse ramps, etc.

Reverse gear

The ability of a self-propelled cleaning machine (see above) to independently move not only forward but also backward. This feature greatly improves the manoeuvrability of the machine, which can be important in tight spaces and also makes work easier. On the other hand, it complicates the design and consequently affects the cost. Therefore, reverse gear is found mainly in top-class models, which are heavy.

Performance

The performance of a cleaning machine is the area that the unit can process in an hour.

Usually, the specs indicate the maximum performance achieved under perfect conditions. It may turn out to be somewhat lower due to the specs of the room, the presence of old dirt and other factors. However, the theoretical difference is usually quite consistent with the actual one. For example, models for 1000 m2/h and 2000 m2/h will differ in performance approximately by two times. So, according to this parameter, it is quite possible to evaluate different models and compare them with each other.

Note that high performance requires a powerful motor and capacious tanks, which affects the dimensions, weight and cost of the unit. Therefore, excessive performance is just as undesirable as insufficient. In addition, more powerful machines usually have a larger working width and are not well suited for rooms with an abundance of narrow passages and nooks and crannies.

As for the actual values, models less than 1000 m2/h belong to the entry-level. It is the specs that most household machines have (see "Type"). A value from 1000 to 2000 m2/h is relatively low for professional sweepers and the average for scrubber dryers. 2000 – 3000 m2/h is considered a fairly solid performance, and models of more than 3000 m2/h is extremely ra...re. These are mostly high-end sweepers (it is extremely difficult to achieve such characteristics in scrubbers).

Usually, the specs indicate the maximum performance achieved under perfect conditions. It may turn out to be somewhat lower due to the specs of the room, the presence of old dirt and other factors. However, the theoretical difference is usually quite consistent with the actual one. For example, models for 1000 m2/h and 2000 m2/h will differ in performance approximately by two times. So, according to this parameter, it is quite possible to evaluate different models and compare them with each other.

Note that high performance requires a powerful motor and capacious tanks, which affects the dimensions, weight and cost of the unit. Therefore, excessive performance is just as undesirable as insufficient. In addition, more powerful machines usually have a larger working width and are not well suited for rooms with an abundance of narrow passages and nooks and crannies.

As for the actual values, models less than 1000 m2/h belong to the entry-level. It is the specs that most household machines have (see "Type"). A value from 1000 to 2000 m2/h is relatively low for professional sweepers and the average for scrubber dryers. 2000 – 3000 m2/h is considered a fairly solid performance, and models of more than 3000 m2/h is extremely ra...re. These are mostly high-end sweepers (it is extremely difficult to achieve such characteristics in scrubbers).

Motor power

Rated power of the engine installed in the car.

Most often, this paragraph gives the total engine power. However, in units with a suction function - for example, scrubber dryers (see "Type") - only the power transmitted to the brushes can be indicated here. In such cases, the total power can be determined by summing the motor power and the suction power (see below). These details should be clarified separately. We also note that in self-propelled models (see above), part of the engine power is spent on moving the unit, which is why the useful power of such machines is lower than that of similar non-self-propelled equipment. In light of this, only models with the same movement format can be directly compared by this indicator - only self-propelled or only non-self-propelled.

Overall, higher motor power results in higher efficiency and productivity. However, there is no strict dependence here, and devices with similar engine characteristics can differ markedly in practical characteristics - productivity, working width, etc. So when choosing, it makes sense to pay attention first of all to these characteristics - especially since for some units (in particular, many robots) the engine power may not be supplied at all. As for specific power values, in the most modest equipment - in particular, household scrubber dryers - it does not exceed 600 W ; 600 – 1200 W can be called average, 1200 – 1800 W is above average, and in powerful heavy units there are even more respectable values.

Most often, this paragraph gives the total engine power. However, in units with a suction function - for example, scrubber dryers (see "Type") - only the power transmitted to the brushes can be indicated here. In such cases, the total power can be determined by summing the motor power and the suction power (see below). These details should be clarified separately. We also note that in self-propelled models (see above), part of the engine power is spent on moving the unit, which is why the useful power of such machines is lower than that of similar non-self-propelled equipment. In light of this, only models with the same movement format can be directly compared by this indicator - only self-propelled or only non-self-propelled.

Overall, higher motor power results in higher efficiency and productivity. However, there is no strict dependence here, and devices with similar engine characteristics can differ markedly in practical characteristics - productivity, working width, etc. So when choosing, it makes sense to pay attention first of all to these characteristics - especially since for some units (in particular, many robots) the engine power may not be supplied at all. As for specific power values, in the most modest equipment - in particular, household scrubber dryers - it does not exceed 600 W ; 600 – 1200 W can be called average, 1200 – 1800 W is above average, and in powerful heavy units there are even more respectable values.

Suction power

Working power of the machine for suction.

The effort with which the unit draws in pollution during operation directly depends on this indicator. The greater this effort, the higher the quality of cleaning and the more effective cleaning. On the other hand, even in the heaviest and most performant models, the suction power does not exceed 1200 W — it simply does not make sense to increase it further. In addition, we note that with an increase in the width of the grip, the suction power must also be increased, otherwise, the efficiency will decrease. It means that only models of the same type with the same or almost the same working width can be compared in terms of suction power.

The effort with which the unit draws in pollution during operation directly depends on this indicator. The greater this effort, the higher the quality of cleaning and the more effective cleaning. On the other hand, even in the heaviest and most performant models, the suction power does not exceed 1200 W — it simply does not make sense to increase it further. In addition, we note that with an increase in the width of the grip, the suction power must also be increased, otherwise, the efficiency will decrease. It means that only models of the same type with the same or almost the same working width can be compared in terms of suction power.

Side brushes

The number of side brushes provided in the design of the sweeper.

Brushes located on the sides of the body are used in sweepers and vacuum sweepers (see "Type"). They complement the main brush of the unit (usually installed in front of the body or under it) and have two main tasks. The first task is to ensure effective cleaning of hard-to-reach places, such as the space near walls or curbs, floor areas under radiators or shelves, etc. The design of the brush is such that it easily sweeps dust out of narrow spaces. The second task is to increase the working width (see below) and the corresponding increase in productivity (see above).

Modern sweepers can be equipped with 1 or 2 side brushes. In the second case, such devices are installed on both sides of the unit. And the standard location of a single brush is on the right. The brushes can be made detachable — this can be useful for working in narrow spaces, where manoeuvrability and compactness are more important than coverage.

Brushes located on the sides of the body are used in sweepers and vacuum sweepers (see "Type"). They complement the main brush of the unit (usually installed in front of the body or under it) and have two main tasks. The first task is to ensure effective cleaning of hard-to-reach places, such as the space near walls or curbs, floor areas under radiators or shelves, etc. The design of the brush is such that it easily sweeps dust out of narrow spaces. The second task is to increase the working width (see below) and the corresponding increase in productivity (see above).

Modern sweepers can be equipped with 1 or 2 side brushes. In the second case, such devices are installed on both sides of the unit. And the standard location of a single brush is on the right. The brushes can be made detachable — this can be useful for working in narrow spaces, where manoeuvrability and compactness are more important than coverage.

Brush speed

Sweeper brush rotation speed in standard operating mode. This parameter is relevant mainly for scrubbers (see "Type"). However, it can also be indicated for sweeping units powered by an electric motor (in a mechanical drive, the brush speed will depend on the actual speed of movement).

Theoretically, the higher the speed, the more thorough the cleaning is, and the more efficiently the machine handles old, dried dirt. However, there are two important points. The first is that modern technology can use not only rotating but also vibrating brushes. In the latter case, the number of revolutions is indicated by the number of vibrations per minute. And if the speed of rotating brushes usually does not exceed 400 rpm, then in vibration brushes it ranges from 700 to 1500 rpm and even higher. The second point is that the quality of cleaning depends not only on speed but also on the diameter of the brush: the edges of a larger brush at the same speed will move faster. With all this in mind, only models with the same principle of operation (rotation or vibration) and a similar working width can be compared in terms of the number of revolutions.

Theoretically, the higher the speed, the more thorough the cleaning is, and the more efficiently the machine handles old, dried dirt. However, there are two important points. The first is that modern technology can use not only rotating but also vibrating brushes. In the latter case, the number of revolutions is indicated by the number of vibrations per minute. And if the speed of rotating brushes usually does not exceed 400 rpm, then in vibration brushes it ranges from 700 to 1500 rpm and even higher. The second point is that the quality of cleaning depends not only on speed but also on the diameter of the brush: the edges of a larger brush at the same speed will move faster. With all this in mind, only models with the same principle of operation (rotation or vibration) and a similar working width can be compared in terms of the number of revolutions.

Working width

The width of the space that a harvester can cover in one pass. In models with removable side brushes (see above), this paragraph indicates figures only for the unit itself, and the width of the grip with brushes is specified separately (see below).

The large working width is convenient when working in large open spaces - it allows you to complete the job in fewer passes. In turn, machines with a small working width - and, accordingly, a relatively narrow body - are more passable, they are better suited for environments with a large number of hard-to-reach places. So you should choose based on this parameter taking into account the characteristics of the premises/territories being served.

The large working width is convenient when working in large open spaces - it allows you to complete the job in fewer passes. In turn, machines with a small working width - and, accordingly, a relatively narrow body - are more passable, they are better suited for environments with a large number of hard-to-reach places. So you should choose based on this parameter taking into account the characteristics of the premises/territories being served.

Working width (with brush)

The width of the area that the sweeper is able to cover with one side brush. See above for more details on such brushes; here we note that they are used in sweepers (see "Type"), to increase the working width and increase overall efficiency, and a single side brush is usually installed on the right side of the housing.

In general, a larger working width improves efficiency in large open areas, but reduces flotation in hard-to-reach areas. At the same time, it is worth noting that additional brushes have almost no effect on the width of the case; so it is better to evaluate the machine's patency by its own working width, without a brush — see "Working Width". However, in some models, only the width with the brush is given — this usually means that the brush is made non-removable; in such cases, you can focus on the overall dimensions of the unit.

In general, a larger working width improves efficiency in large open areas, but reduces flotation in hard-to-reach areas. At the same time, it is worth noting that additional brushes have almost no effect on the width of the case; so it is better to evaluate the machine's patency by its own working width, without a brush — see "Working Width". However, in some models, only the width with the brush is given — this usually means that the brush is made non-removable; in such cases, you can focus on the overall dimensions of the unit.

Working width (with 2 brushes)

The width of the area that the sweeper is able to cover using the two side brushes. See above for more details on such brushes; here we note that they are used in sweepers (see "Type") to increase the working width and for efficient processing of hard-to-reach places (for example, spaces under curbs and walls). The presence of two brushes allows you to effectively process such places, regardless of which side the machine is turned to them.

In terms of working width, in general, a wider working width improves efficiency in large open areas, but worsens flotation in hard-to-reach places. At the same time, it is worth noting that additional brushes have almost no effect on the width of the case; so it is better to evaluate the machine's patency by its own working width, without brushes — see "Working Width". However, in some models, only the width with brushes is given — this usually means that the brushes are made non-removable; in such cases, you can focus on the overall dimensions of the unit.

In terms of working width, in general, a wider working width improves efficiency in large open areas, but worsens flotation in hard-to-reach places. At the same time, it is worth noting that additional brushes have almost no effect on the width of the case; so it is better to evaluate the machine's patency by its own working width, without brushes — see "Working Width". However, in some models, only the width with brushes is given — this usually means that the brushes are made non-removable; in such cases, you can focus on the overall dimensions of the unit.

Suction width

Suction width provided by the unit. It is indicated mainly for floor scrubbers and window vacuums (see "Type"). In the first case, it refers to the width of the suction beam; in the second — the width of the working nozzle.

The width of the suction beam in scrubber dryers is usually slightly larger than the overall working width — it allows one to collect the water used in cleaning effectively. The size of the suction beam in some models of this type reaches 75 cm. In turn, in window vacuum cleaners the suction width corresponds to the actual working width. Most often, this figure is about 28 – 29 cm. it is believed that such values give an optimal ratio between performance and dimensions/weight of the unit. However, there are also more miniature models — in some devices, the width of the nozzle does not exceed 17 cm.

The width of the suction beam in scrubber dryers is usually slightly larger than the overall working width — it allows one to collect the water used in cleaning effectively. The size of the suction beam in some models of this type reaches 75 cm. In turn, in window vacuum cleaners the suction width corresponds to the actual working width. Most often, this figure is about 28 – 29 cm. it is believed that such values give an optimal ratio between performance and dimensions/weight of the unit. However, there are also more miniature models — in some devices, the width of the nozzle does not exceed 17 cm.

Additional nozzle

The width of the additional nozzle provided with the device.

Additional attachments are mainly supplied with window models (see "Type"). Such a nozzle is usually made narrower than the main one — it makes it easier to work on small glasses and in hard-to-reach places. However, there is also the opposite option: a small capture width in the device itself, increased by using an additional nozzle.

Additional attachments are mainly supplied with window models (see "Type"). Such a nozzle is usually made narrower than the main one — it makes it easier to work on small glasses and in hard-to-reach places. However, there is also the opposite option: a small capture width in the device itself, increased by using an additional nozzle.

Brush pressure

The pressure of the brush on the surface to be cleaned, provided by the machine.

This parameter is relevant mainly for scrubbers (see "Type"). The higher the downforce, the more effectively such a machine handles complex tasks such as removing old, stubborn dirt or cleaning bumpy floors. On the other hand, higher pressure requires more weight for the entire unit and a more powerful motor, which affects the cost and dimensions. In addition, too intensive processing can damage some types of flooring.

In light of all this, when choosing a scrubber for brush pressure, it is necessary to take into account the specifics of the planned application. For a flat floor with a delicate covering, which is not subject to severe pollution, a pressure of 20 – 30 kg will be enough. If the covering does not require careful handling, but the high intensity is not critical, you can choose a unit with a pressure of up to 50 kg; and in the most powerful and heavy models, this figure can be 60 kg or more.

This parameter is relevant mainly for scrubbers (see "Type"). The higher the downforce, the more effectively such a machine handles complex tasks such as removing old, stubborn dirt or cleaning bumpy floors. On the other hand, higher pressure requires more weight for the entire unit and a more powerful motor, which affects the cost and dimensions. In addition, too intensive processing can damage some types of flooring.

In light of all this, when choosing a scrubber for brush pressure, it is necessary to take into account the specifics of the planned application. For a flat floor with a delicate covering, which is not subject to severe pollution, a pressure of 20 – 30 kg will be enough. If the covering does not require careful handling, but the high intensity is not critical, you can choose a unit with a pressure of up to 50 kg; and in the most powerful and heavy models, this figure can be 60 kg or more.

Detergent tank

The volume of the cleaning solution tank installed in the harvester.

This parameter is directly related to the device type (see above) and some features of its functionality. So, in powerful self-propelled scrubbers (see "Type") tanks with a volume of tens of liters can be provided, while in floor cleaning robots the capacity does not exceed 1 liter (and in some models it is only 120 mL). So, according to this characteristic, only units of the same type with similar functionality can be compared with this indicator. With such a comparison, it is worth proceeding from the fact that a more capacious tank, on the one hand, allows you to work longer without refueling, on the other hand, it affects the dimensions and weight.

This parameter is directly related to the device type (see above) and some features of its functionality. So, in powerful self-propelled scrubbers (see "Type") tanks with a volume of tens of liters can be provided, while in floor cleaning robots the capacity does not exceed 1 liter (and in some models it is only 120 mL). So, according to this characteristic, only units of the same type with similar functionality can be compared with this indicator. With such a comparison, it is worth proceeding from the fact that a more capacious tank, on the one hand, allows you to work longer without refueling, on the other hand, it affects the dimensions and weight.

Waste detergent tank

The volume of the waste solution tank installed in the harvester.

Such tanks are equipped exclusively with floor scrubbers (including household ones) and window models (see "Type"): we recall that both of them are designed for suction of the solution from the treated surface. In general, the larger the tank, the less often it will have to be emptied, but the larger the dimensions and weight of the unit. Therefore, manufacturers usually choose this indicator taking into account the type and characteristics of the application of the machine. So, in devices for windows, which are held in the hands during operation, the capacity of the tanks for the spent solution is small — usually about 150 – 200 mL; this is quite enough, taking into account the format of application, and at the same time, such additional weight does not create inconvenience during work. In turn, scrubbing machines use containers of several liters or even tens of liters; usually, a specific volume directly depends on the overall “weight category” and the performance of the machine.

Such tanks are equipped exclusively with floor scrubbers (including household ones) and window models (see "Type"): we recall that both of them are designed for suction of the solution from the treated surface. In general, the larger the tank, the less often it will have to be emptied, but the larger the dimensions and weight of the unit. Therefore, manufacturers usually choose this indicator taking into account the type and characteristics of the application of the machine. So, in devices for windows, which are held in the hands during operation, the capacity of the tanks for the spent solution is small — usually about 150 – 200 mL; this is quite enough, taking into account the format of application, and at the same time, such additional weight does not create inconvenience during work. In turn, scrubbing machines use containers of several liters or even tens of liters; usually, a specific volume directly depends on the overall “weight category” and the performance of the machine.

Waste tank

The volume of the garbage tank provided in the design of the harvester. The garbage tank is equipped with sweeper and suction sweeper units (see above). The larger the capacity of this container, the more garbage it can hold and the less often it will have to be emptied. On the other hand, this indicator can significantly affect the weight and dimensions of the sweeper, despite the fact that for small volumes of cleaning (for example, occasional sweeping of the path at the exit from the garage), a capacious garbage tank is simply not required. Therefore, manufacturers usually choose the capacity of this tank based on the general class of the harvester and the work for which it is designed.

Battery type

The type of battery used in the car with the appropriate power supply (see above). The type is indicated by the technology used to manufacture the battery.

- Ni-Cd. One of the oldest modern technologies. Such elements are capable of operating at high discharge currents, which is especially important for heavy and powerful equipment with high energy consumption. In addition, they charge fairly quickly, can withstand cold work and temperature changes without any problems, and are relatively inexpensive. One of the main disadvantages of nickel-cadmium batteries is the so-called. memory effect - a decrease in capacity if charging was carried out until completely discharged. However, this disadvantage can be compensated for by using high-quality chargers and following operating rules. But the clear disadvantage of this variety is environmental unsafety in production and disposal; It is precisely this that limits the use of Ni-Cd batteries in modern technology.

- Ni-Mh. A technology created in an attempt to improve the performance of the nickel-cadmium batteries described above. The attempt was quite successful: while maintaining the main advantages of their predecessors, nickel-metal hydride elements are at the same time less susceptible to the memory effect and more environmentally friendly. Their disadvantages include slightly increased cost and specific rules for long-term storage.

— Li-Ion. Lithium-ion batteries are notable primarily for their hig...h charge density - in other words, they have high capacity with small dimensions and weight. This is especially important for compact devices such as robots or manual window cleaners (see “Type”). In addition, such batteries are practically not subject to the “memory effect”. Among the disadvantages of this technology, in addition to cost, it is worth mentioning sensitivity to high and low temperatures, as well as the likelihood of “accidents” in abnormal conditions: failure of the built-in controller with overcharge or overdischarge, overheating or short circuit can lead to swelling, electrolyte leakage and even fire.

- Li-Po. A type of lithium-ion battery (see above), in which a polymer (gel) electrolyte is used instead of a liquid electrolyte. This design provides additional advantages over the original Li-Ion technology: lithium-polymer batteries have an even greater charge density, and the likelihood of “accidents” with explosions and fires in them is noticeably reduced. The main disadvantages of such power supplies are their rather high cost and the requirement to maintain optimal temperature conditions.

— Gel. In this case, we are usually talking about gel lead-acid batteries, similar to those used in cars. Such batteries are significant in weight, so they are used exclusively in heavy harvesting equipment, where several kilograms of battery weight are unnoticeable against the background of the weight of the machine itself. Among the practical advantages of such batteries, it is worth noting good capacity, durability, the ability to easily withstand deep discharge, as well as resistance to low temperatures and temperature changes.

- Ni-Cd. One of the oldest modern technologies. Such elements are capable of operating at high discharge currents, which is especially important for heavy and powerful equipment with high energy consumption. In addition, they charge fairly quickly, can withstand cold work and temperature changes without any problems, and are relatively inexpensive. One of the main disadvantages of nickel-cadmium batteries is the so-called. memory effect - a decrease in capacity if charging was carried out until completely discharged. However, this disadvantage can be compensated for by using high-quality chargers and following operating rules. But the clear disadvantage of this variety is environmental unsafety in production and disposal; It is precisely this that limits the use of Ni-Cd batteries in modern technology.

- Ni-Mh. A technology created in an attempt to improve the performance of the nickel-cadmium batteries described above. The attempt was quite successful: while maintaining the main advantages of their predecessors, nickel-metal hydride elements are at the same time less susceptible to the memory effect and more environmentally friendly. Their disadvantages include slightly increased cost and specific rules for long-term storage.

— Li-Ion. Lithium-ion batteries are notable primarily for their hig...h charge density - in other words, they have high capacity with small dimensions and weight. This is especially important for compact devices such as robots or manual window cleaners (see “Type”). In addition, such batteries are practically not subject to the “memory effect”. Among the disadvantages of this technology, in addition to cost, it is worth mentioning sensitivity to high and low temperatures, as well as the likelihood of “accidents” in abnormal conditions: failure of the built-in controller with overcharge or overdischarge, overheating or short circuit can lead to swelling, electrolyte leakage and even fire.

- Li-Po. A type of lithium-ion battery (see above), in which a polymer (gel) electrolyte is used instead of a liquid electrolyte. This design provides additional advantages over the original Li-Ion technology: lithium-polymer batteries have an even greater charge density, and the likelihood of “accidents” with explosions and fires in them is noticeably reduced. The main disadvantages of such power supplies are their rather high cost and the requirement to maintain optimal temperature conditions.

— Gel. In this case, we are usually talking about gel lead-acid batteries, similar to those used in cars. Such batteries are significant in weight, so they are used exclusively in heavy harvesting equipment, where several kilograms of battery weight are unnoticeable against the background of the weight of the machine itself. Among the practical advantages of such batteries, it is worth noting good capacity, durability, the ability to easily withstand deep discharge, as well as resistance to low temperatures and temperature changes.

Voltage

The voltage of the battery used in the machine with the corresponding type of power supply. This parameter is not key when choosing; it may only be needed when looking for a third-party charger or a replacement/spare battery, as well as for specific calculations related to capacity (see below).

Battery capacity

The capacity of the battery installed in the cleaning machine with the appropriate power supply.

In theory, a higher capacity allows you to work longer on a single charge, but in practice everything is not so simple. Firstly, the autonomy is also affected by the energy consumption of the machine, and it is determined mainly by the engine power (see above). Secondly, the actual amount of energy stored in the battery depends not only on the capacity in ampere hours, but also on the operating voltage in volts. Therefore, only batteries with the same voltage can be compared with each other in terms of capacity in Ah (or convert ampere-hours to watt-hours using a special formula and compare the results). And it is best to evaluate the autonomy of the unit by the directly stated operating time (see below).

In theory, a higher capacity allows you to work longer on a single charge, but in practice everything is not so simple. Firstly, the autonomy is also affected by the energy consumption of the machine, and it is determined mainly by the engine power (see above). Secondly, the actual amount of energy stored in the battery depends not only on the capacity in ampere hours, but also on the operating voltage in volts. Therefore, only batteries with the same voltage can be compared with each other in terms of capacity in Ah (or convert ampere-hours to watt-hours using a special formula and compare the results). And it is best to evaluate the autonomy of the unit by the directly stated operating time (see below).

Autonomy time

Operating time of a battery-powered cleaning machine on one charge of a standard battery.

This parameter itself is quite approximate: it is most often indicated for standard operating modes and simple conditions. However, the actual autonomy is usually not very different from the stated one; so, based on the stated operating time, it is quite possible to both evaluate the capabilities of different models and compare them with each other.

This parameter itself is quite approximate: it is most often indicated for standard operating modes and simple conditions. However, the actual autonomy is usually not very different from the stated one; so, based on the stated operating time, it is quite possible to both evaluate the capabilities of different models and compare them with each other.

Charging time

The time required to fully charge the battery of cleaning machine (see "Power supply").

The larger the battery, the longer it may take to charge it. On the other hand, this moment also depends on the type of battery. In addition, special technologies are being used to speed up the process. So two machines with a similar battery capacity can differ in charging times.

The larger the battery, the longer it may take to charge it. On the other hand, this moment also depends on the type of battery. In addition, special technologies are being used to speed up the process. So two machines with a similar battery capacity can differ in charging times.

Noise level

The noise level created by the harvesting machine during operation.

Low noise levels are important for the comfort of both the operator and others; the latter is especially true in some specific places such as hospitals or kindergartens. On the other hand, the higher the power, the louder, as a rule, the unit operates and the more difficult it is to reduce this noise to a certain level; despite the fact that in many cases high volume operation is not a particular problem. So you should specifically look for a “quiet” cleaning machine only if a low noise level is more critical for you than high cost and/or reduced power.

When assessing specific loudness values, it is worth considering that the decibel used to indicate the noise level is a non-linear quantity. Therefore, the easiest way is to evaluate specific values using comparative tables. Here's a simplified table for the range that most modern harvesting machines fit into:

55 dB - background noise in an office without special noise sources;

60 dB - loud conversation;

65 dB - city street with average traffic intensity;

70 dB - a conversation between several people in a raised voice.

75 dB – high power vacuum cleaner.

80 dB - traffic noise on a busy street.

Low noise levels are important for the comfort of both the operator and others; the latter is especially true in some specific places such as hospitals or kindergartens. On the other hand, the higher the power, the louder, as a rule, the unit operates and the more difficult it is to reduce this noise to a certain level; despite the fact that in many cases high volume operation is not a particular problem. So you should specifically look for a “quiet” cleaning machine only if a low noise level is more critical for you than high cost and/or reduced power.

When assessing specific loudness values, it is worth considering that the decibel used to indicate the noise level is a non-linear quantity. Therefore, the easiest way is to evaluate specific values using comparative tables. Here's a simplified table for the range that most modern harvesting machines fit into:

55 dB - background noise in an office without special noise sources;

60 dB - loud conversation;

65 dB - city street with average traffic intensity;

70 dB - a conversation between several people in a raised voice.

75 dB – high power vacuum cleaner.

80 dB - traffic noise on a busy street.

Filter area

The working area of the filter, which is regularly equipped with a cleaning machine.

In this case, we are talking about a filter designed for fine dust. Its area as a whole is a secondary parameter, it is selected by the manufacturer in accordance with the general level and performance of the unit — so that the filter performs its function efficiently enough and at the same time is not too bulky. If models with similar characteristics differ in this indicator, note that a larger filter is more expensive and takes up more space, but it has to be cleaned less often.

In this case, we are talking about a filter designed for fine dust. Its area as a whole is a secondary parameter, it is selected by the manufacturer in accordance with the general level and performance of the unit — so that the filter performs its function efficiently enough and at the same time is not too bulky. If models with similar characteristics differ in this indicator, note that a larger filter is more expensive and takes up more space, but it has to be cleaned less often.

Power cord length

The length of the mains cord provided in the machine with the appropriate power supply (see "Power supply").

A long cord allows you to move further away from the outlet but can get tangled under your feet and create inconvenience. Therefore, manufacturers choose the length of the power cord by the specs of a particular model: for example, a window robot (see "Type") is quite enough 4 – 5 m, and in heavy scrubbing units, the length of the wire can exceed 20 m.

A long cord allows you to move further away from the outlet but can get tangled under your feet and create inconvenience. Therefore, manufacturers choose the length of the power cord by the specs of a particular model: for example, a window robot (see "Type") is quite enough 4 – 5 m, and in heavy scrubbing units, the length of the wire can exceed 20 m.

Weight

The total weight of the cleaning machine. Usually, weight is indicated with empty tanks for detergent, waste, fuel, etc. At the same time, additional equipment, such as side brushes, may or may not be taken into account. Such equipment has a very small weight compared to the machines themselves. And, when installed/removed, does not seriously affect the mass of the entire machine.