Many types of materials are described above in the "String Material" section, most of what is written there is also relevant for braids — especially when the string is wrapped with the same material from which it is made. Here we will only touch on some of the nuances associated with individual materials.

— Copper. It is used in different types of strings — nylon for classical guitar, bronze for "acoustics", etc. as an inexpensive alternative to bronze.

The copper braid gives a quite clean and balanced sound, but it sounds more muffled than "silver" (see below), and does not have the features characteristic of ordinary or phosphor bronze.

— Silver. Most often, in this case, it means copper coated with a thin layer of silver. This braid is a classic option for "bass" nylon strings used in classical guitars. The silver coating gives the copper braid the necessary sonority, while the price of such a combination is quite affordable. On the other hand, silver wears off rather quickly. But combining a

"silver" braid with a steel base does not make sense, and although such strings are found on the market, they do not have any special advantages over pure steel or bronze.

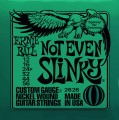

— Nickel.

Nickel braid is popular primarily in electric guitar strings. In this case, the core of the string can be made both from the same material and from steel; the first option giv

...es a denser and smoother sound, the second one is brighter and more sonorous (although not as sonorous as pure steel). And the unequivocal advantages of nickel windings are softness (due to which the wear of the nut is reduced) and “slipperiness” (fingers slide well along the strings, which makes it easier to perform some playing techniques).

— Cobalt. Another braid material used in electric guitar strings. Cobalt has a high magnetic permeability, which allows the strings to interact more effectively with the pickups, increases the output level and (according to the manufacturer) improves the frequency response. In addition, this material is resistant to wear, has good durability, and fingers glide well over it. The disadvantage of cobalt is a rather high cost (both due to the price of the material itself, and because of the “premium” positioning of strings with cobalt braid).

— Nylon. This material is used for winding metal, usually steel strings, including in bass guitars. Nylon braid can have a different design, sometimes quite unusual. So, in some strings, only a “case” is made of nylon — a protective coating, inside of which there is a string with a sheath (also metal). In other models, a nylon coating is applied to the metal wire, and after that the string is wrapped with it. In both cases, synthetics prevent string contamination from sweat and dirt from fingers, and also improves fit to the nut and prevents flattening of the winding from constant pressing. As a result, the string retains its original sound (roughly speaking, "plays like new") longer than when uncoated. On the other hand, this material noticeably muffles the strings and does not allow to achieve a bright, “iridescent” sound.

— Nickel-plated chrome. A variant found in double bass strings. Chromium provides the tape with hardness and durability, reducing wear on contact with the fingerboard and with the bow. Nickel somewhat muffles the sonorous timbre of chrome, giving the instrument the necessary softness of sound. However, for a number of reasons, this option has not received much distribution.

— Nickel-plated bronze. Bronze braid complemented by nickel plating. Found in acoustic guitar strings. The coating provides corrosion resistance to the strings, extending their life and making them easier to store. As for acoustics, nickel somewhat softens and “warms” the sound of yellow bronze.

— Bronze. In this case, the so-called yellow bronze (actually brass). It is mainly used in strings for acoustic guitars. Yellow bronze is characterized by a fairly bright and sonorous sound, often with a characteristic clanging (which many musicians consider a virtue). However, this material is sensitive to corrosion and requires special attention during storage — otherwise the bronze braid will begin to oxidize, which will negatively affect both appearance and sound.

— Phosphor bronze. A darker variety of bronze, with a reddish tinge. Also used primarily in acoustic guitars. The sound of such strings, in comparison with yellow bronze, turns out to be softer and smoother, without ringing and clanging, but with more pronounced depth and clear bass.

— Aluminium bronze. A type of bronze in which the main component, in addition to copper, is aluminium. Both in terms of coloration of the sound, and outwardly similar to yellow bronze, while it can be brighter and more brilliant. However, the main advantage of this material over yellow bronze is its high resistance to corrosion — such a braid normally tolerates even a long stay in conditions of high humidity. On the other hand, such strings cost accordingly.

— Aluminium. Aluminium winding is found in strings for bowed instruments of the "higher" range (in particular, violins and violas), both steel and nylon. This material is quite versatile, it is suitable for providing a sonorous, bright sound, and for softer, warmer tones; It can be said that the sound of aluminium braided strings depends more on the material of the string itself. With all this, aluminium is durable and resists bow friction well.

— Titan. Another material used in strings for bowed instruments. In fact, it is a “premium version” of the aluminium described above: titanium is stronger and more durable, in addition, it practically does not stretch, but it also costs more.The diameter of the strings in the set, from thinnest to thickest.

Thicker strings, all other things being equal, provide more volume and richness to the sound, have more overtones, and generally sound richer and warmer (high frequencies are less pronounced in the sound). However, these strings require more tension, which can make them uncomfortable for beginners and inexperienced players who are unaccustomed to high force; and the duration of the sound is relatively low. Conversely, thinner strings are softer to the touch, require less effort, give better sustain, but are thinner and more prone to rattle. Detailed recommendations on the optimal string thickness for different cases can be found in special sources (including documentation for the instrument itself and reference materials from string manufacturers).

Note that the diameter of the strings is directly related to the tension (see below), so one of these parameters is often indicated in the characteristics.