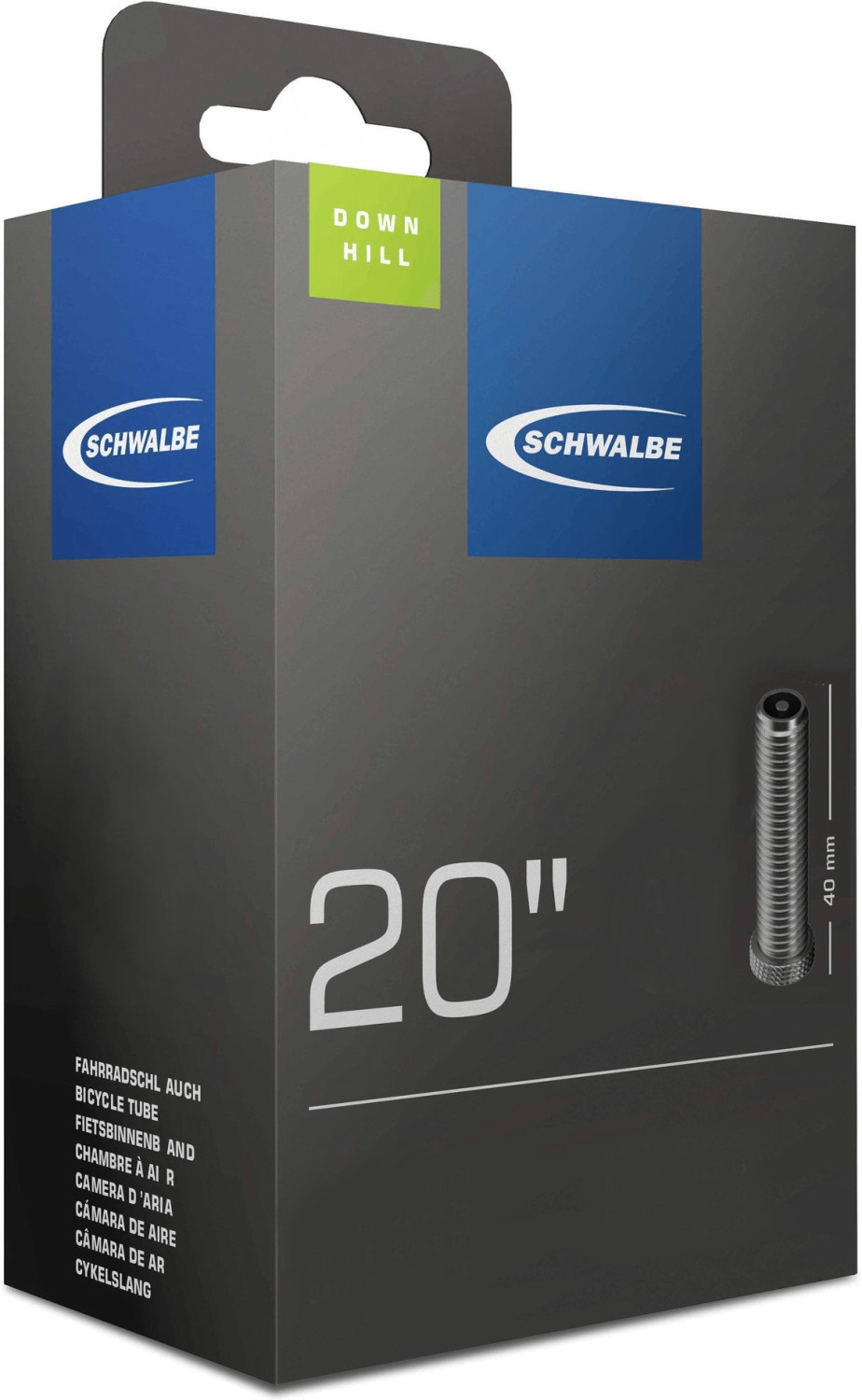

Schwalbe Av3 16 X 1.75 / 2.50' Schrader 40mm TYR-SCH-SCH-DEF-3752

|

Buy Schwalbe Av3 16 X 1.75 / 2.50' Schrader 40mm TYR-SCH-SCH-DEF-3752

When you make a purchase through links on our site, we may earn an affiliate commission.

Schwalbe Schwalbe Inner Tube AV 2A Black 16 Inch Black | £6.00 | ||||

Schwalbe Av3 16 X 1.75 / 2.50' Schrader 40mm TYR-SCH-SCH-DEF-3752 | £6.99 | ||||

A bicycle tube is predominantly made of Butyl rubber. Butyl is a very elastic and airtight synthetic rubber. But as with the tire other fillers are necessary to make up the rubber compound. The quality of a tube can vary significantly depending on the rubber compound. For instance Schwalbe tubes have extremely high air retention and elasticity. This high elasticity allows a wide range of different tire sizes to be covered. There is a difference between heat molded and autoclave tubes. Vulcanizing in a mold improves the uniformity of wall thickness thus reducing weight and improving air retention. For this reason the autoclave tubes which can be produced easier have become less common over the past years. Schwalbe tubes have always been made using the heat molding process. Every tube also needs a valve which is bonded to the tube during the vulcanizing process. Why Choose Schwalbe Tubes? Besides the quality of the ingredients the purity of the Schwalbe rubber compound is decisive for the quality of the tube. Before extrusion the basic material is forced through a total of seven filters under enormous pressure. All tubes are inserted and inflated into a mould for the vulcanization process. Only this ensures an even wall thickness and high air retention. All tubes are inflated and stored for 24 hours to test for air retention. Afterwards every tube is carefully checked individually by visual inspection. The Schwalbe tube has been valued by German bicycle dealers for its high reliability for many years. A tube covers many tire sizes through its high elasticity and quality. Tube no. 17 works with tyres from a width of 28 mm up to 47 mm - a great advantage for stockholding in the trade. At the same time it is proof of the quality of the tube. All valves are nickel-plated and threaded. The valve core is always replaceable. Also Schwalbe tubes with a classic bicycle valve can be inspected for pressure as they have a high-pressure valve core.

Product description is based on database from online stores. Be sure to verify all information directly with seller before purchasing.

What to give your husbandIdeas for useful and pleasant gifts for your husband, taking into account his hobbies and preferences

Which brand of bike is best to buy?Bike brands that guarantee you quality, reliability and riding comfort

How to place an order?How to add store?

Remember that online store is responsible for accuracy of information about price, warranty and delivery!

You may be interested in