Modern Technologies in the Tire Industry

We independently test the products and technologies that we recommend.

1. Technologies for Damage Resistance and Self-healing

1.1 Run Flat: tyres that allow you to continue driving even after a puncture

This technology is based on a reinforced tire sidewall design that allows you to continue driving at speeds of up to 80 km/s even when the tire pressure has completely dropped. This allows you to get to a tire shop without having to take out and put on a spare tire. On average, you can drive from 50 to 100 km on a “flat” Run Flat tire - the specific permissible mileage is usually specified by the tire manufacturer.

A significant advantage of Run Flat is that with a sharp loss of pressure in the tire at high speed, control over the car is not lost. However, the technology is not without its drawbacks: such tires are heavy, which increases the load on the suspension parts of the car, they are difficult to repair and require special tire fitting equipment for removal / installation on the wheel rim. Run Flat tires allow you to continue driving even with a complete drop in pressure in the air chamber, but their use is mandatory in conjunction with a tire pressure monitoring system (TPMS), otherwise the driver may not notice a puncture.

There is no single marking for tires with Run Flat technology - each manufacturer calls it in its own way:

- Run Flat — Nokian ;

- RF or Run Flat — Pirelli ;

- RFT (Run-Flat Tire) - Bridgestone ;

- SSR (Self Supporting Run-Flat) - Continental ;

- RFT (RunOnFlat) or EXM (Extended Mobility Technology) - Goodyear ;

- ZP (Zero Pressure) - Michelin ;

- HRS (Hankook Runflat System) - Hankook ;

- ZPS (Zero Pressure System) - Yokohama ;

- DSST (Dunlop Self-Supporting Technology) - Dunlop ;

- XPR (eXtended Runflat Performance) - Kumho.

1.2. Self-Sealing: materials for puncture regeneration

This technology is aimed at self-sealing minor punctures in the tire tread area. Typically, such punctures occur from nails, screws and other similar objects. A special viscous sealant is applied to the inner under-tread layer of the corresponding tires, which instantly tightens small holes in the contact patch area.

It should be noted that the technology does not apply to serious tread damage and does not protect against side cuts of the tire. It only helps to cope with minor punctures (up to 5 - 6 mm, no more). Self-Sealing tires (https://ek.ua/list/337/pr-42361/) are identical to regular tires, except for a slightly increased weight, which is due to the presence of an additional under-tread layer of sealant in their design.

The following technology marking options are available:

- SelfSeal - Michelin ;

- Seal Inside — Pirelli ;

- ContiSeal - Continental ;

- B-Seal - Bridgestone ;

- Sealguard - Hankook ;

- K-Seal - Kumho.

1.3. Aramid Sidewall Technology: reinforced sidewalls made of aramid fiber

The pioneer in the use of aramid fibers to strengthen the sidewalls of tire products is the Finnish company Nokian Tyres. High-strength Kevlar threads are added to the sidewalls of tires manufactured using Aramid Sidewall technology. They provide increased resistance to side punctures, cuts and impacts, reduce the risk of tire damage when driving off-road, and minimize the likelihood of tire rupture when hitting curbs, potholes and sharp objects. The technology is used in individual rubber samples from the Nokian Hakkapeliitta, Rotiiva, Hakka, Rockproof and WR model lines.

Other reputable manufacturers of car tires do not yet use the technology on a large scale, but individual products with aramid fiber reinforcement are also found in their portfolio.

2. Technologies for Enhanced Comfort

2.1. Silent Technology: Foam materials for reducing road noise

The Silent Technology innovation group refers to the use of special foam materials in the internal structure of the tire to reduce road noise. They reduce resonant air noise to improve the level of acoustic comfort while driving.

In addition to sound-absorbing foam, these quiet tires use an optimized tread pattern with a carefully designed arrangement of functional blocks, which reduces vibrations and noise from contact with the road surface.

Noise reduction technology is marked with the following symbols depending on the specific tire manufacturer:

- Silent Technology - Toyo;

- SilentDrive — Nokian;

- Silent Tire Technology - Yokohama;

- B-Silent — Bridgestone;

- ContiSilent — Continental;

- Acoustic Technology - Michelin;

- SoundComfort Technology - Goodyear;

- PNSC (Pirelli Noise Canceling System) - Pirelli;

- Sound Absorber — Hankook;

- Noise Shield - Dunlop;

- K-Silent System — Kumho.

2.2. Adaptive Tread Design: adaptive tread

Tyres with a "dynamic" tread pattern that adapts to a variety of external factors. The technology is aimed at ensuring stable grip properties when driving on various types of roads and in different weather conditions. Depending on the specific implementation, the tyre tread elements can open and close additional channels, flexibly adjusting to dry or wet conditions, as well as adapting to different road surfaces.

At the same time, the technology helps to evenly distribute the load across the entire plane of the contact patch - adaptation of the contact area with the road maintains an optimal balance of movement in dry and rainy weather, prevents uneven wear of the tread.

As usual, different tire manufacturers call the technology differently or may not have a separate name at all:

- Adaptive Design - Michelin;

- ContiAdapt — Continental;

- Active Braking Technology - Goodyear.

2.3. Multi-Compound Technology: rubber compound composition for improved grip and comfort

The multi-formula compound involves the use of different rubber mixtures, each of which is optimized for specific conditions. For example, harder rubber in the central core of the tread improves the wear resistance and durability of the tire, while softer sidewalls provide a comfortable ride. Other driving qualities of the tire may also be affected - grip, resistance to overheating, rubber behavior on dry, wet and snowy roads, etc.

The technology is called differently:

- Multi-Cell Compound - Bridgestone;

- Multi-Layer Compound - Michelin;

- Multi-Tread Technology - Dunlop;

- Multi-Compound Tread - Toyo.

3. Eco-friendly Technologies

3.1. Energy Saver: Minimizing rolling resistance

Energy Saver is a proprietary development of tire manufacturers from the French company Michelin. However, similar technologies are also found in other venerable players in the tire arena. This innovation is based on reducing the level of rolling resistance. This minimizes the energy costs for wheel rotation, which leads to reduced fuel consumption and reduced exhaust emissions into the atmosphere.

3.2. Eco-Friendly Materials: Using materials that reduce carbon footprint

"Green" or eco-tires also make a significant contribution to environmental protection. Eco-friendly rubber is made from recycled raw materials and contains natural materials in the compound formula. In terms of driving performance, it also has a low rolling resistance, which helps reduce fuel consumption and, as a result, a noticeable reduction in the carbon footprint.

3.3. AirFree Concept: Airless Tires

The concept of puncture-proof tires from Bridgestone, which do not require inflation and are not afraid of punctures. In fact, such tires do not have an air chamber - instead, interwoven spokes made of thermoplastic are used, providing the necessary elasticity and shock absorption.

Airless tires have not yet reached mass production. They can be seen on the wheels of conceptual models of cars, some bicycles and scooters. The technology has potential for the near future.

4. Smart and Digital Technologies

4.1. Tire Pressure Monitor System: tire pressure monitoring system

The TPMS (Tire Pressure Monitoring System) monitors tire pressure and warns the driver if it deviates from the permissible norm. Information from the corresponding sensors is sent to the on-board computer or display in the car. If the pressure falls below a safe level, the system activates a warning signal.

There are two main types of tire pressure monitoring:

- direct - sensors are installed inside each tire;

- indirect - wheel rotation data from ABS and ESP systems is used.

The first implementation option will cost more, but it shows the actual tire pressure and is highly accurate. Indirect TPMS systems are less accurate, do not show specific pressure, but they are also cheaper.

4.2. Smart Tires: tires with sensors to transmit data on condition and pressure

Truly smart tires are still concepts. The essence of the technology comes down to the use of a system of sensors and special multilayer materials. Based on the sensor readings, the tire collects a wide variety of information:

- tire pressure;

- road surface temperature;

- the level of road grip (which is useful for more correct operation of the ABS and ESP systems);

- degree of tread wear;

- Smart tires can also potentially notify the driver of cuts and punctures.

and on the connected smartphone.

It is assumed that the results obtained from the sensors will be transmitted directly to the vehicle's on-board computer. This ensures real-time control of driving parameters.

4.3. Cyber Tire: tires that transmit data on road conditions in real time

Cyber tires are a variation on the theme of smart tires from the Italian tire makers from Pirelli. Sensors on board the rubber analyze road conditions (whether the road is dry, wet or icy), sense vertical load, lateral and longitudinal forces, determine the type of road surface, read the contact patch and angle of inclination, air temperature and pressure level, the number of wheel revolutions and even tread wear. The received data is transmitted to the car control system and can be used by electronic safety systems. One of the features of Cyber Tire technology is the ability to prevent aquaplaning and loss of traction, which potentially promises accidents.

5. Technologies for Grip and Safety

5.1. HydroGrip: special tread to minimize the risk of aquaplaning

HydroGrip technology consists of using materials with improved hydrophobicity and voluminous aqua drainage channels in the tire design for instant cleaning of the contact patch from excess water masses. Simply put, it is aimed at increasing the safety and performance of rubber on wet roads. The technology is designed to maintain stable grip properties, support responsive vehicle control and increase braking efficiency in wet conditions.

Tyres with HydroGrip tread are found in the model ranges of Goodyear and Firestone(one of the subsidiary brands of the leading company Bridgestone).

5.2. 3D-Lamela Technology: improved grip on snow and ice thanks to 3D sipes

In winter tires, along with the usual sipes, special three-dimensional sipes (usually wavy) are located in the tread blocks. 3D sipes have a multifaceted internal structure - when in contact with the road, they can close, open or change shape. Under normal road conditions, three-dimensional sipes experience vertical pressure, and when the wheels slip, they also experience longitudinal pressure. Under the influence of longitudinal forces, the sipes move apart and expose additional internal edges, which increase the tire's ability to grip a slippery road.

with slippery and icy road surfaces.

3D-Lamela technology and its derivatives are widely used in the production of winter tires. This design innovation significantly improves the grip properties of rubber in various road and weather conditions.

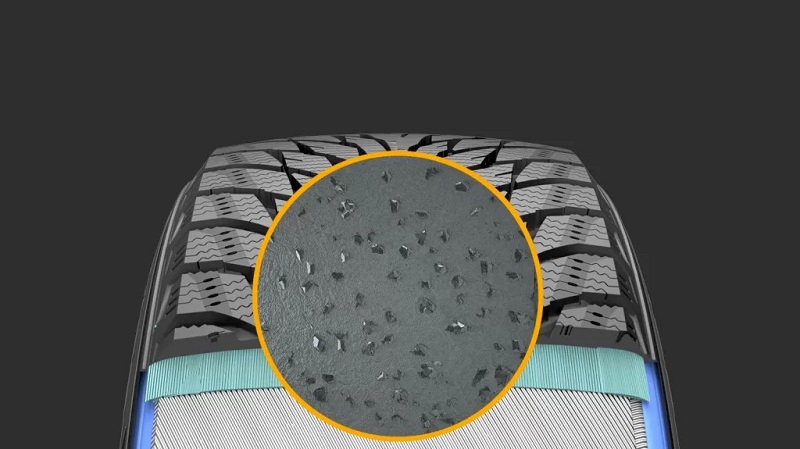

5.3. Cryo-Crystal Technology: Crystals in rubber for improved grip on ice

A signature innovation from Nokian Tires, used in the brand's winter friction tires. It is a crystalline additive to the rubber compound. Hard particles with sharp edges Cryo Crystal act like microspikes, literally biting into the road surface with their edges. As a result, excellent grip on slippery and icy winter roads is ensured.

on slippery and icy road surfaces.

6. Durability Technologies

6.1. Multi-Air Chamber: tires with multiple air chambers for increased reliability

Multi-chamber tires contain several separate air chambers inside. If one of the chambers is punctured or the pressure drops, the tire retains its tightness, allowing you to continue driving without the need for immediate rubber repair. At the same time, the Multi-Air Chamber design improves the stability of the car's behavioral characteristics and ensures driving comfort. In reality, the technology is shown using the example of a concept tire from Bridgestone.

7. Technologies for Winter Conditions

7.1. Snow Claw Technology: studded or adaptive treads for snowy and icy roads

Snow Claws may refer to anti-skid studs or special elements and projections in the winter tire tread design that enhance grip on snow and ice. The technology is aimed at increasing safety and improving vehicle control in winter conditions.

7.2. Winter Siping: additional sipes for improved grip on slippery surfaces

We are talking about abundant lamellaization of winter tire tread blocks. A dense network of multidirectional slits significantly increases the number of cutting edges on the tire tread surface. The lamellas provide additional grip properties and help the tread to adapt to uneven road surfaces much faster.

8. High-performance Technologies

8.1. Track Performance Technology: solutions for racing cars that increase grip at high speeds

Technological innovations aimed at improving the performance of track and high-performance tyres. Track Performance Technology developments provide optimum grip, vehicle control and stability when driving at high speeds on race tracks.

8.2. Dynamic Response: technology for improved handling in sporty conditions

Dynamic Response technology is responsible for instant reactions to steering commands, which is extremely important for improving the car's response in sports conditions. Specifically, Dynamic Response is a development of tire makers from Michelin. The technology is based on a rigid under-tread belt made of aramid fibers, which instantly reacts to changes in the tire rotation angle. This achieves the highest possible precision in entering turns.

Was this article useful? Yes0 No0 |

Articles, reviews, useful tips

All materials