What is HRC knife hardness?

We independently test the products and technologies that we recommend.

If you are looking for kitchen knife, then large selection of solutions is offered in our catalog. Need model for hiking, hunting or other outdoor activities? Then we recommend that you familiarize yourself with corresponding tourist assortment. By the way, both there and there you can filter knives by HRC.

What is Rockwell Hardness (HRC)?

Hardness of cutting tool is fairly important indicator that determines its ability to resist deformation under applied contact pressure (that is, working with various materials - cutting, splitting, chopping, sawing). This parameter is important not only for knives, but also, for example, for cutters, circular and band saws. In simple terms, it depends on hardness whether the blade retains its integrity under the influence of the material being processed (cartilage or bone, bar or branch, tin can, etc.).

Measurement methods

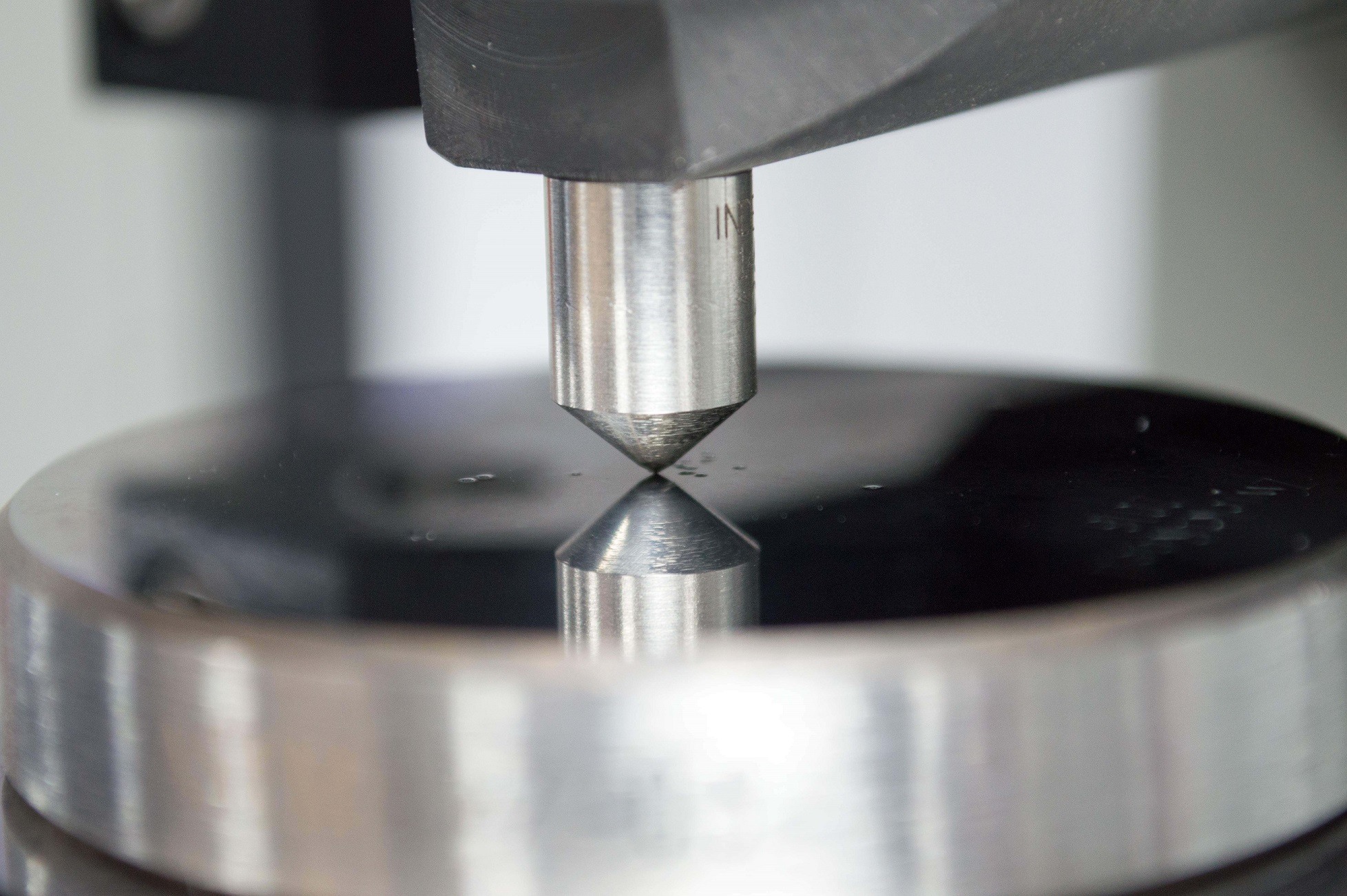

Hardness index of blade can be measured by various methods. Most often, diamond tips or hardened metal balls are used for testing. These accessories are called indenters and are usually pressed into the material to be tested and thus hardness is assessed. But such an algorithm of actions unites only group of static methods of measurement. There are also dynamic tests, for example, according to Shore, it is also the rebound method. In this case, height of rebound of the indenter (striker) from test material is fixed, and during measurements, special equipment is used - scleroscope.

It is static methods (with indentation) that are considered more universal and more often used. Similar text, according to its own methodology, was once invented by the above-mentioned Shor, as well as by Vickers, Brinell and Rockwell. Latter option is considered the most popular and reliable for measuring hardness of cutting tools, moreover, corresponding procedure is even regulated by ISO 6508-1 standard. It is logical that it is advisable to compare different knives according to one method, and this is Rockwell today.

|

| Rockwell’s method involves pushing tip into test material. |

Rockwell method and its scales

To determine Rockwell hardness, 11 different scales are provided, that is, in fact, there are 11 sub-methods. They differ in intendor (it is a steel ball or a diamond tip with different shape, diameter, etc.), pressure exerted during test (load) and, of course, scope, for example, to assess hardness of bronze or aluminium - one scale, and for solid metals - another. Submethods are assigned Latin letters (A, B, C, etc.). As a result of tests, in addition to numerical value of hardness, abbreviation HR (general designation of the Rockwell method) + the letter of the scale, that is, for example, HRA 71 or HRC 59, must also be indicated.

If tests are carried out with steel, and knife blades are most often made from it, then main sub-method is HRC. Within framework of indicators on this scale, one can compare hardness of blades.

To test knives, special equipment is used - hardness tester, diamond cone with rounded top as an indenter, and the applied load is 150 kg. In fact, first test text is performed with slight pressing effect (10 kg), after that the main one. Difference in depth of immersion of indenter into the steel is also recorded, after which digital hardness tester immediately displays hardness value, and when using simpler equipment, it remains to perform simple calculations using formulas.

|

| Digital hardness tester shows HR value immediately. |

Benefits of Rockwell hardness assessment

Why is Rockwell method so popular? Here are its main advantages:

- during test, metal is not destroyed: only small imprint remains on it;

- simplicity of measurements - in presence of hardness tester, microscope or other equipment is not required;

- high speed of assessment - without preparation, test itself is completed in just 5 seconds;

- when working with steel, alloy does not need to be polished or cleaned beforehand.

What determines hardness of knife blade?

HRC value of steel directly depends on composition of alloy and subsequent heat treatment of metal (quenching). Defining "number of Rockwells" chemical element in blade is carbon. So, the higher its consistency in steel, the harder it will be. For example, popular American-made alloy 420HC and its European counterpart, X46Cr13, contain at least 0.46% carbon. In this case, hardness is usually about 57 HRC. But premium Japanese steel grade ZDP-189 has 6 times more carbon (almost 3%), respectively, and value on Rockwell scale approaches 69 HRC.

It turns out that already by grade of steel, in general terms, one can judge level of hardness. But considerable scatter within an alloy with same composition is not excluded, because final HRC value is affected by additional heat treatment (quenching) and metal tempering. These stages differ significantly between different knife manufacturers, and therefore hardness varies. You don’t need to go far for examples, for example, even in Spyderco line there are Tenacious and Byrd Hawkbill models: both blades are made of 8Cr13MoV alloy, but first has hardness of 56, and second has 59 HRC.

|

| Hardness can be increased by hardening metal. |

By the way, due to different heat treatment, some manufacturers indicate not one hardness value, but range, for example, from 56 to 58 Rockwell units. The fact is that special tests are usually carried out by steel manufacturers themselves, and knife brands do not make corresponding measurements after hardening, especially when it comes to handmade models or limited batches.

It is also worth noting that not all manufacturers give HRC values for their products. Many American and European companies limit themselves to steel grade only. Moreover, there are brands that even keep the alloy or its composition secret, which is typical, for example, for Victorinox Swiss knives. In this sense, the presence of at least a range of hardness for the buyer will be much more informative than the complete absence of information about the materials used to manufacture the blade.

What gives high hardness knife?

High HRC values are often identified with premium, expensive steels and, accordingly, with knives of the highest price category. This is partly true, because hardness above 60 units on the Rockwell scale is usually found in premium segment models. But knife is rarely purchased for reasons of status, and above all for applied tasks, whether it is quick work in kitchen or necessary operations for bushcraft, that is, survival in forest and in nature. What gives increased hardness?

First of all, high HRC values mean the ability of blade to maintain sharpness for a long time. That is, such knife does not have to be sharpened often, which is important both in kitchen and in outdoor applications.

|

| Good knife is a sharp knife, and for a long time. |

Also, hardness directly determines wear resistance of blade: the higher the HRC, the better the product will resist destruction under the influence of friction, including during normal cutting movements, planing, etc.

Of course, the harder the blade, the stronger and stronger its metal, all other things being equal. In general, it is believed that high hardness has positive effect on overall reliability and durability, and is an indirect confirmation of quality. But not everything is so simple, since high HRC indicators also have disadvantages.

What are the disadvantages of too hard knives?

It is known from basics of physics that the higher the hardness of material, the lower its plasticity (elasticity). Applied to knives, this means greater fragility of the blade, including its tip and cutting edge. In practice, this translates into the possibility of blade crumbling under inadequate loads. In addition, owner of knife, seeing high HRC values, sometimes exaggerates its capabilities, believing that product is ready for any test.

|

| Consequence of brittleness is the risk of cutting edge chipping . |

For example, in field, you can easily lose part of solid blade due to additional side load, including when trying to plan knots. Similarly, in kitchen, cutting edge of knife with high HRC value can be damaged if it accidentally hits bone when cutting meat. Similar fate can befall the hunter. To restore knife after such unpleasant incidents, simple sharpening is not enough, you will have to re-create slopes, which requires both certain skills and special equipment.

Second minus of high HRC values directly emerges from pluses. Knife keeps its sharpness really well, that is, it does not get dull, but someday you still have to sharpen it, and when applied to hard steels, this is very laborious process. For example, simplest pocket sharpener is unlikely to cope with this task.

Third ambiguous moment of large "number of Rockwells" is associated with composition of the alloys. Yes, you can increase hardness by hardening stainless steel with moderate carbon content, but most often high HRC values are characteristic of carbon steels. In them, stability of maintaining sharpness is sometimes achieved by reducing corrosion resistance. Suppose, for field conditions and kitchen, an increase in hardness due to an increase in sensitivity to moisture is definitely a dubious undertaking.

What is the optimal HRC value for blade?

Recently, there has been afashion for knives with an increased level of Rockwell hardness. Moreover, if earlier many wanted model with value of at least 58 HRC, now they often consider 60 units or even more. If we focus on such high rates, then we will probably have to increase budget for purchase and take products from premium steel grades. At the same time, such an overpayment does not guarantee any reference, impeccable performance properties, in addition to maintaining sharpness for a long time.

Traditionally, the normal hardness value can be considered as 55 HRC. And for most knives. As tribute to fashion, you can focus on range from 55 to 58 Rockwell units. Such blades keep sharpness of the cutting edge well, are not too laborious when sharpening, and are balanced in terms of wear resistance and elasticity.

For hunting and pocket everyday models, you can focus on range from 52 to 58 HRC. Higher values for specific field applications are undesirable due to the inevitable increase in brittleness.

For kitchen knives, spread of balanced scores is slightly wider, namely 52 - 62 Rockwell units. Housewives will like models that are closer to the upper limit because they rarely need to be sharpened. At the same time, they will be very easy and convenient to cut soft foods. To minimize risk of chipping the cutting edge of hard kitchen knife , cutting board made of wood or silicone can be recommended.

Conclusions and tips for choosing hardness of knife

Before buying knife, of course, you should take into account hardness of its blade, as it affects the preservation of blade sharpness, laboriousness of sharpening, overall wear resistance, strength, elasticity (brittleness). The banal pursuit of high HRC values (above 58 or 60 on the Rockwell scale) is not best approach, which will only result in an overpayment and does not guarantee flawless performance of functions assigned to it by the product.

|

| Solid kitchen knife requires careful handling. |

Main guidelines for choosing can be considered precisely the tasks pursued and main scenarios for using knife. Below are some recommendations in this regard:

- for housewives who do not have special sharpening skills, kitchen model with either relatively low hardness (from 52 to 55 units), or, conversely, with high HRC values (about 60), is suitable. In the first case, knife will dull faster, but simple manual sharpener guarantees easy restoration of sharpness. Very hard knife will allow you to enjoy operation without additional maintenance, but still require more careful handling;

- if cutting model is needed, for example, machete or fillet knife, then hardness index is higher than 55 and 57 HRC, respectively, should not be considered. Otherwise, fragility and the likelihood of damage to the edge increase;

- if you need most versatile tourist knife that can open cans, chop wood, stir up fire or even dig the ground, then you should take products with relatively soft stainless steel - up to 55 HRC. Yes, they quickly become dull, but they sharpen without problems, and are also not prone to chipping: edge under heavy loads can be slightly deformed, but will remain intact;

- for light-moving tourists who do not take extra luggage on road, very hard knives (from 58 units) are suitable. With them, you will not need additional sharpeners or musats in your backpack. But for long expedition, it is better to consider softer models, otherwise, at the most inopportune moment, you can be left with dull product. And it is very problematic to return steel sharpness with value of about 60 Rockwells in field conditions;

|

| For hiking, it is better to tak not too hard knife. |

- throwing knives are characterized by low hardness - usually even about 52 units or less. They need good elasticity, which, when dropped, protects against breaking, chipping or coloring blade;

- if there is choice between high hardness and corrosion resistance, then for hike and kitchen, second point is priority;

- For experienced users who know how to handle solid knives, it is certainly wise to consider buying them. For sharpening, they will need to be given to professionals or special machines should be used, which are recommended primarily for craftsmen and enthusiasts of working with cutting tools.

|

| Sharpening hard knife is an art. |

In conclusion, it should be noted that hardness is not the only indicator that helps with right choice of knife. Ideally, you should evaluate dozens of other indicators, including blade profile and geometry ,angle of sharpening, shape and handle material, overall size, ergonomics and even aesthetics. If this is the first such purchase, then we recommend looking at the brand (country of origin, reputation), steel brand and, if possible, hardness. Experienced users already know that choosing great knife is difficult but almost always fascinating exercise with many variables and compromises when making final decision.

Was this article useful? Yes0 No0 |

Articles, reviews, useful tips

All materials